PE Series Jaw Crusher

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

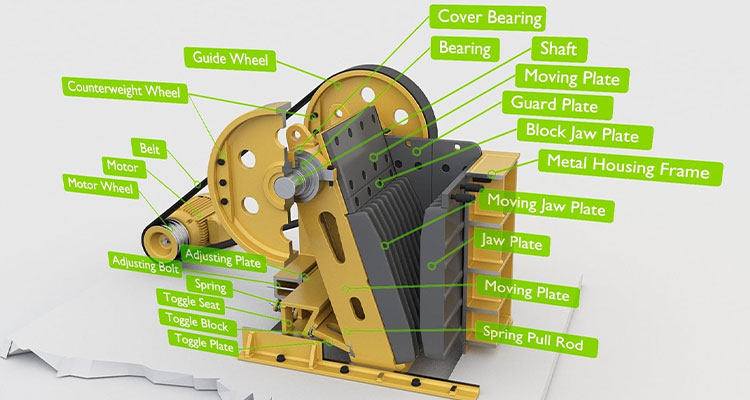

Jaw crusher is a commonly used coarse crushing equipment in sand and gravel production line. It can process all kinds of hard ore and rock materials whose compressive strength is not higher than 280MPa. It has the advantages of simple structure, durable, reliable operation, large crushing ratio, Energy saving, low noise, easy maintenance and other features, it is a commonly used crushing equipment in the sand and gravel industry.

HIGH YIELD AND HIGH EFFICIENCY

The symmetrical crushing cavity is deepened, the actual entrance width is consistent with the nominal width, and the crushing ratio is large.

ADVANCED TECHNOLOGY

The flywheel, slot block and counterweight block have passed strict technical parameter review, effectively reducing the vibration level of the equipment and improving the smooth operation of the equipment.

AUTOMATION

The motor can be started and stopped under load, and can also work when the crushing chamber is completely full or overloaded, with a high degree of automation.

ENERGY SAVING AND LOW NOISE

Using high-quality cast steel assembly, movable claw assembly and flywheel, forging and processing heavy-duty eccentric shaft, the quality is reliable, and the single machine is energy-saving.

The crushing method of the jaw crusher is a curved extrusion type, and its working principle is to simulate the jaw movement of animals. When working, the motor drives the belt and pulley through the eccentric shaft to move the movable jaw up and down. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, so that the movable jaw is pushed close to the fixed jaw, and the materials are crushed many times through the extrusion, friction and grinding between the two jaws. When the movable jaw descends, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw leaves the fixed jaw under the action of the pull rod and the spring, and the crushed material is discharged freely through the discharge port at the lower part of the jaw cavity under the action of gravity. With the continuous rotation of the motor, the movable jaw periodically crushes and discharges materials to achieve mass production.

| Model | Feeding port size (mm) | Feed size (mm) | Discharge size (mm) | Capacity (tph) | Motor power (kw) | Weight (t) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|

| PE600*900 | 600*900 | ≤500 | 65-160 | 90-180 | 55-75 | 17 | 2290*2206*2370 |

| PE750*1060 | 750*1060 | ≤630 | 80-140 | 110-320 | 90-110 | 29 | 2655*2302*3110 |

| PE900*1200 | 900*1200 | ≤750 | 95-165 | 220-450 | 110-132 | 58 | 3800*3166*3045 |

| PE1000*1200 | 1000*1200 | ≤850 | 200-300 | 280-560 | 110-160 | 69 | 5350*4280*3050 |

| PE1200*1500 | 1200*1500 | ≤1020 | 150-300 | 400-800 | 160-220 | 100.9 | 6380*5310*3710 |

| PE1500*1800 | 1500*1800 | ≤1200 | 210-360 | 520-1100 | 280-355 | 132 | 7460*6235*4249 |