XGP Series Single Cylinder Hydraulic Cone Crusher

CAPACITY

FEED SIZE

CAPACITY

FEED SIZE

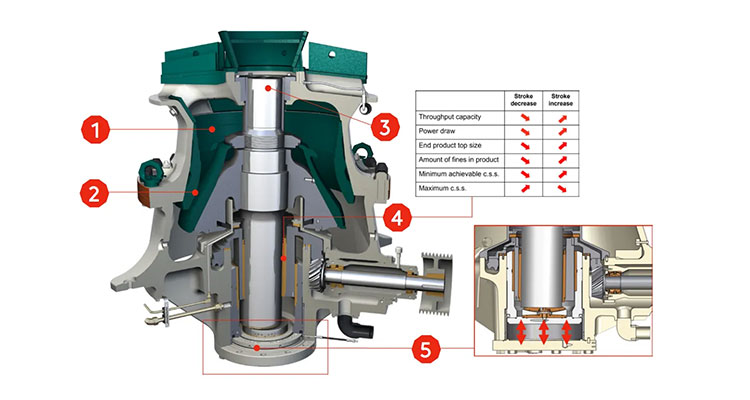

XGP single-cylinder hydraulic cone crusher is a combination of mechanical, hydraulic, automation, intelligent control and other technologies. It is suitable for medium and fine crushing of medium-hard materials. It has simple and reliable structure, low failure rate, low production cost and strong operation stability. With the advantages of convenient maintenance, it is widely used in metallurgy, construction, hydropower, transportation, building materials and other industrial fields, and occupies an important share in the market.

OPTIMIZED DESIGN

The body has higher strength and more reliable operation. The optimized design of the crushing chamber ensures high lamination crushing efficiency, while the crushing effect of the equipment is not affected by the wear of the liner.

MULTI-CAVITY SWITCHING

The fully automatic control system provides users with various control modes such as manual control, automatic loading, and automatic double discharge ports.

INTEGRATED HYDRAULIC LUBRICATION

The hydraulic system adopts high-pressure design to meet the general pressure requirements, and the equipment operates with high pressure, which improves the reliability of the hydraulic system.

LOW MAINTENANCE COST

Spherical bearings are used to replace the bushing design, which prolongs the life of the bearings.

The rotation of the motor drives the pulley or coupling, the drive shaft and the conical part to make the eccentric shaft do periodic swinging motion under the axis line. After the material enters the crushing cavity from the feed port, it is squeezed, ground and kneaded by the mutual impact of the eccentric shaft and the wall of the rolling socket to produce crushing effect. The hydraulic insurance system can remove the fault objects from the top of the support sleeve and the fixed cone through hydraulic pressure when the machine has an iron fault or a stuffy car.

| Model | Type | Feed port (mm) | Max feed size (mm) | Discharge port size (mm) | Motor power (kw) | Host weight (kg) | Capacity (tph) |

|---|---|---|---|---|---|---|---|

| XGP100 | A | 150 | 120 | 7-39 | 90 | 5800 | 35-135 |

| B | 130 | 105 | |||||

| C | 100 | 85 | |||||

| XGP200 | A | 225 | 180 | 12-45 | 200-220 | 12700 | 85-350 |

| B | 150 | 120 | |||||

| C | 80 | 60 | |||||

| XGP300 | A | 225 | 180 | 10-50 | 250-280 | 16700 | 140-490 |

| B | 150 | 125 | |||||

| C | 80 | 60 | |||||

| XGP500 | A | 280 | 220 | 12-45 | 315-355 | 27000 | 245-715 |

| B | 150 | 125 | |||||

| C | 100 | 80 |

| Model | Type | Feed port (mm) | Max feed size (mm) | Discharge port size (mm) | Motor power (kw) | Host weight (kg) | Capacity (kg) |

| XGP100S | A | 320 | 250 | 35-100 | 75-90 | 9500 | 140-520 |

| B | 250 | 210 | |||||

| XGP200S | A | 340 | 280 | 35-105 | 160-200 | 13400 | 160-610 |

| B | 250 | 210 | |||||

| XGP300S | A | 380 | 320 | 35-100 | 220-250 | 18200 | 250-870 |

| B | 280 | 240 | |||||

| XGP500S | A | 500 | 420 | 45-105 | 280-315 | 32700 | 300-1400 |

| B | 380 | 320 |